7 Ways to Take Your Packaging from Average to Awesome

Wednesday, June 27, 2012 at 5:07PM

Wednesday, June 27, 2012 at 5:07PM 1. Design with your CUSTOMERS in mind

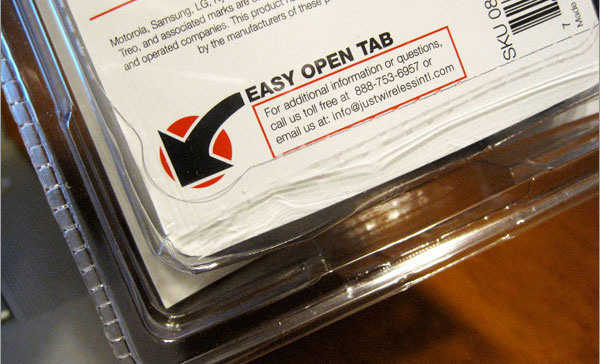

When designing packaging for your product, the most important thing to keep in mind is the end-user. Ask yourself - Does this packaging convey the key points about the product? Is it easy to use? Does it drive customers to purchase?

When we developed this packaging for Just Wireless’ cell phone accessories, we focused on creating a positive user experience. No more wrestling with scissors and plastic shards just to get your product free from the packaging.

Photo found here

Photo found here

2. Think about the RETAILERS - and their guidelines

Most retailers (small and large) have a set of packaging guidelines that they require the products they stock to follow. Make sure you’re adhering to those guidelines at the beginning stages of packaging development to make sure you don’t spend unnecessary time and money re-designing your packaging later on.

3. Don't forget about the EARTH

Not only is creating eco-friendly packaging good for the earth...it’s good for business. By doing things like re-designing packaging structures to reduce waste and by using 50/70/90% post-consumer recycled paper and biodegradable materials - you’re not only creating a more eco-friendly product line, you’re meeting the packaging standards of retailers like WalMart, Target, & Best Buy.

We worked with MicroInnovations to re-design this packaging line to reduce the amount of plastic material used. And, the packaging for these EcoSpeakers from Merkury Innovations uses recycled paper.

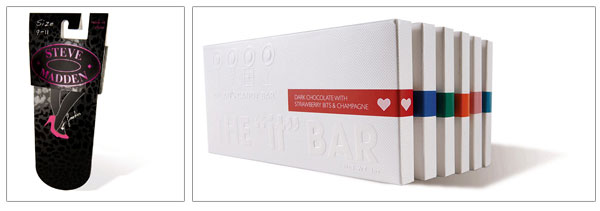

4. Upgrade your packaging by focusing on the details

Details matter when it comes to packaging. They are a great way to catch a buyer’s eye and add to the perceived value of your product. Upgrades like die-cutting, foil stamping, roll embossing, and specialty finishes are affordable when you print in China and can really add that “something special” to a piece.

We helped upgrade this Steve Madden packaging by producing a foil stamped logo and spot UV pattern. This Dylan's Chocolate "it" Bar packaging includes a custom roll emboss pattern plus embossed logos.

5. Think about the part and the whole

When you’re designing your packaging line, don’t just think about the individual components. Think about how your line will look as a whole. How will the pieces look together when they’re in a retail display or on the wall of a store? Does the line have a cohesive look? Are each one of the products identifiable as part of the bigger brand?

6. Think outside the paper box

Paper boxes and plastic inserts may not be the best fit for your product. Sometimes other materials (like wood or tin) are a better choice. If your product is a luxury item or has a higher retail value, customers may appreciate the fact that they can keep the packaging and re-use it after they remove your product.

Instead of using a traditional paper box for chocolates for the Mandarin Oriental Hotel, we helped the client develop a bamboo box that serves as a traveler's keepsake from their stay. Dylan's Chocolate decided a custom printed tin was the best fit for their Ralph Lauren chocolates.

7. Work with experienced professionals

You’ve worked long and hard on your product line. Don’t overlook the value of creating stellar packaging for it. Make sure you’re working with professionals who are not only experts in designing the look of the packaging but are also well-versed in developing the structures required for testing and the logistics of production.

At Laserwave, our team is made up of not just designers but also PACKAGING DEVELOPERS and PRODUCTION EXPERTS. We’d love to discuss you’re latest packaging project with you!